The CNC lathes are one of the most versatile industrial tools And, due to technological advances, CNC lathes are rapidly replacing some of the older and more traditional production lathes such as the multi-spindle, as CNCs have a number of advantages: they can be easily set up and operated, they offer enormous repeatability and first-class precision in production. This machinery has, as its name suggests, a computer system called Computerized numeric control (hence the acronym CNC) capable of perform the different actions previously specified by entering the desired parameters en la máquina sin necesidad de que los operarios tengan que participar durante el proceso. Una de las muchas acciones que puede llevar a cabo esta herramienta es el torneado. Pero, ¿qué es el torneado CNC exactamente? Today we reveal it to you.

What is CNC turning

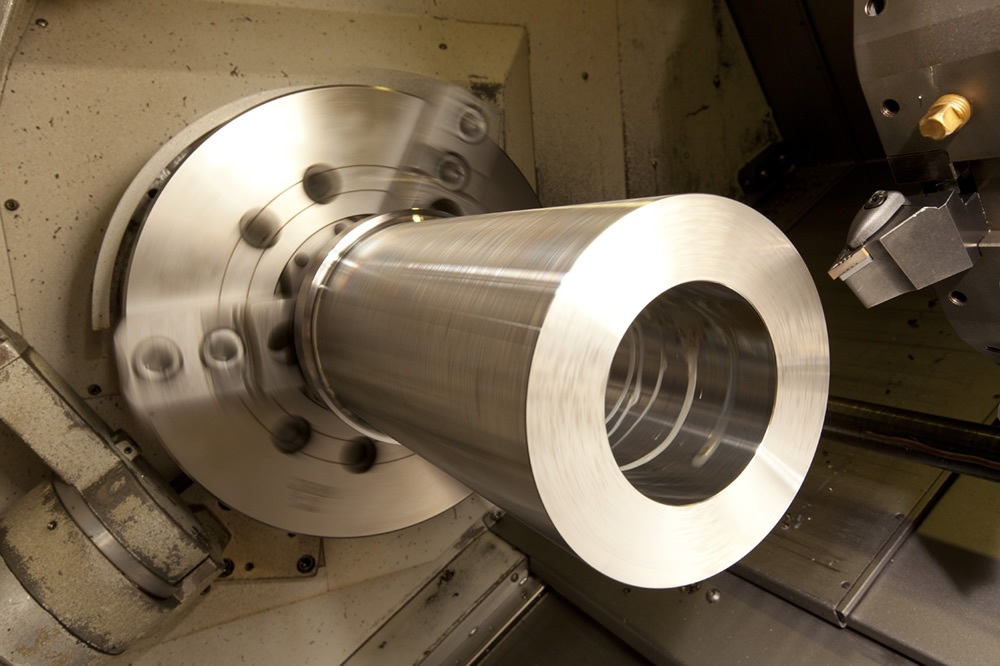

CNC lathes have, at a minimum, the ability to drive the cutting tool under g-code control in 2 axes, called X and Z, although they can carry out a considerable amount of different functionalities. The act of cutting a part on a lathe with these characteristics is called turning. CNC.

A CNC lathe is usually designed to use modern versions of carbide tools and processes. A custom part can be designed, and machine tool paths are often programmed using the CAD or CAM processes. However, a programmer can also manually design a part or tool path. The resulting encoded computer file is loaded into the CNC machine, and the CNC machine will automatically produce the desired parts for which the design has been programmed.

What is it for

A CNC lathe can be used to produce flat surfaces and screw threads or, in the case of ornamental lathes, fairly complex three-dimensional products. In either case, the workpiece is held firmly by one or two centers, of which at least one moves horizontally. However, the material can also be fixed with clamps or pliers.

With CNC turning, the material being worked is sheared slowly. The result is a beautifully finished product or an intricate piece. Since these machines are so versatile, used by many industries such as automotive, electronics, aerospace, the manufacture of firearms, the sports and many more. Some everyday products that can be made by CNC turning are:

- Camshafts

- Crankshafts

- Dining table and chair legs

- Musical instruments

How is the CNC turning process done?

CNC turning is a procedure in which the piece is shaped by eliminating part of the initial material following a specific movement pattern that coincides with the final design Of the piece. Thus, in the same way that a Greek sculptor would carve a beautiful sculpture by chiseling a block of marble to eliminate the one that he does not need, the CNC lathe is in charge of molding (turning) the piece by means of a machining process by chip removal.

The process is simple: the material or piece to be worked is put on the lathe and the material is cut to give it the desired shape. Through Computerized Numerical Control, the machine automatically moves the part around the lathe in the different axes -X, Z and Y- depending on the alpha-numeric data entered in your software, to go making the necessary cuts, grooves or fissures that will give the shape desired to the part.

To make CNC turning possible, the tool consists of two or more carriages to, on the one hand, hold the material or make it rotate on itself depending on the specific needs of the piece to be manufactured; and, on the other, for move around him in different directions to achieve machining the parts in a geometric shape that will give result to the final designed piece.