Surely you have heard of CAD-CAM machining (Computed-aided manufacturing o Computer-aided design and Computed-aided design o Computer-aided manufacturing respectively). This term refers to software that is used to design and manufacture manufactured parts. Below we explain in more detail what CAD-CAM machining is and how it works.

What is CAD-CAM machining?

Let's start step by step. CAD He is responsible for the 2D and 3D plan designs. In other words, it is in the CAD software that the models and assemblies are designed so that the CAM, which we will talk about below, converts the design of those plans into a real object. CAM, for its part, is the type of machining that serves, above all, to control machines and tools. CAD-CAM is, then, the union between design and manufacturing.

He CAD-CAM machining It is used to design products and program their manufacturing process. This parts manufacturing system is used in very specific contexts, such as the manufacture and design of parts for the automotive, aviation, molds, foundry sectors ...

When CAD-CAM did not yet exist, all this process was done by hand, both the design, which was done with pencil on paper; such as manufacturing, where drill, drill and other utensils of this type were used. However, this method had a small margin of error that disappeared with the advent of computers and CAD-CAM software. By this we mean that this type of machining has existed since there are computers.

What are the advantages of CAD-CAM machining?

Designing and manufacturing the parts using software allows eliminate that small margin of error that did exist when all this process was done by hand. The pieces are also much more perfect and have a better finish. In addition, it has been found that CAD-CAM machining increases productivity and optimizes continuous work, as well as you can create a larger number of parts in a much faster and more efficient way.

It has also been found that the CAD-CAM machining supposes a quite significant savings in personnel for companies. To this must be added that it is much safer and a large number of workplace accidents are avoided. It is also beneficial for the planet, since the material can be used much more and less waste is generated.

With all this we want to emphasize that this system has finally come to stay with us. It will probably evolve, but today its existence has become essential.

How to apply CAD-CAM machining correctly?

Now that you know what CAD-CAM machining is, we are going to explain how to apply it correctly in order to enjoy all its advantages.

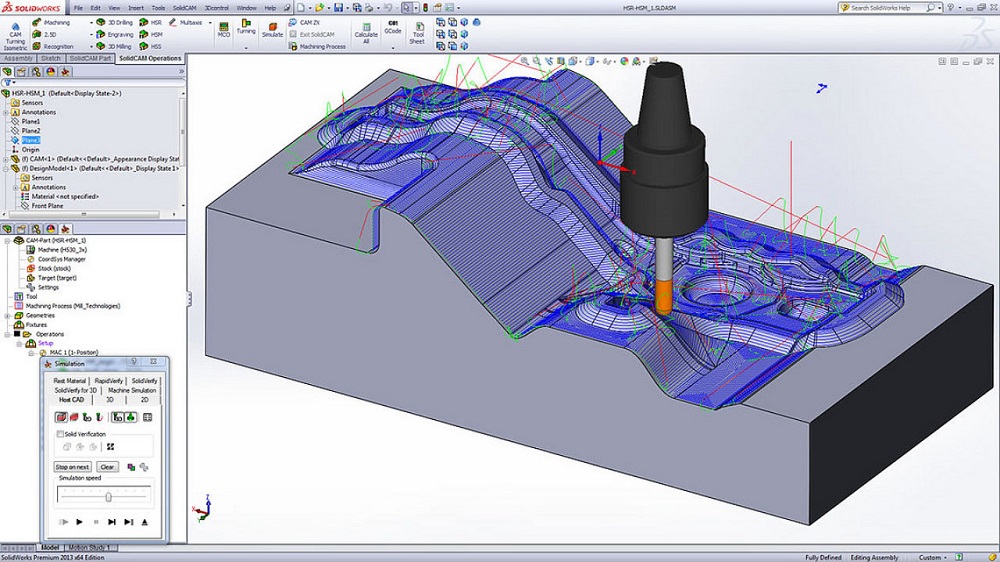

The first thing is to do the 3D part design. The design will have to be processed in the CAM program to be able to create the machining process in different operations. Later you will have to choose the tool, speeds and feeds which will be applied during machining, as well as strategies will have to be chosen. When all this has been done it will be necessary simulate trajectories who will carry the tool, post-process the program in a language that the machine can understand and send it to him.

Prior to execute machining the piece will have to be anchored. Finally, the last step will be to check that the action has been carried out correctly.

Now you know what CAD-CAM machining is, how it can be applied correctly and what are its advantages over the traditional manual method. Although it is a term that can be somewhat complex, in reality it is nothing more than the union of design and manufacture using a computer.