It is very common to find different pieces or tools at home or in other areas and not analyze where each of them come from. When we open our wardrobe, we know what pattern and fashion are. When we look at a piece of furniture, we have a certain idea of how it can get to our home or business. However, with the pieces of metal or other materials we do not question how they have been made perfectly, being suitable to be able to build certain machines or other elements. Therefore, it is important to know, for example, what is cnc milling. As soon as you read this concept, it is very difficult to reach a correct conclusion. However, with a little explanation, part of the process can be correctly understood.

On Mediavilla workshops we are professionals in the creation of all kinds of pieces in order to later build other types of elements. Trust our experience and get those elements you need for yourself or for your business.

What is CNC milling

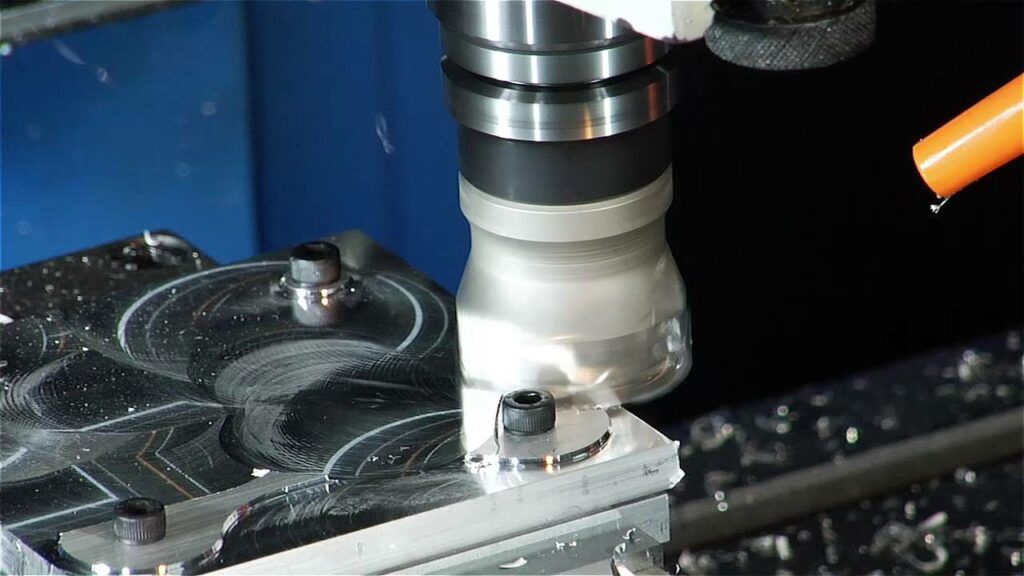

To explain what is CNC milling we have to say that it is a process in which, by means of a CNC milling machine that is controlled by computer, it is possible to obtain a final piece that has been designed from the beginning. For this, its surface, its material and the movement that had to be carried out to obtain it have been taken into account. During the transformation, which takes place with chip removal, a rotating and cutting tool, better known as a "cutter," is rotated, by which the final product is achieved.

The strawberry movement

He process of cnc milling It can be carried out by two types of milling machines. One of them is the horizontal and the other the vertical. Compared to the first, the cutter can move from side to side. Thus, makes it easier for the worker to move the machine away from or closer to the face of the part. In the horizontal milling machine, the spindle axis is, as its name suggests, horizontal. Regarding the vertical milling machine, the machine moves from top to bottom or vice versa. This fact allows it to move towards or away from the top or surface of the part. As in the previous case, in the vertical milling machine, as its name indicates, the spindle is vertical.

Operations using CNC milling

There are many operations that can be carried out related to milling. Each of them will determine what kind of action the cutter will carry out on the part to be developed. Depending on how the machine works, we can talk about different types of processes. Thus, the most prominent are drill milling, engraving milling, face milling, pour milling, pattern surface milling, revolution surface milling, and swept surface milling.

Of course, we are not talking about a piece being better believed in one way or another, but rather it will need a milling or another depending on the objective that the designers have. For example, it is not the same to expect a flat piece than one with curves or teeth. Each shape and design has its own steps and tools.

Differences between a cnc milling machine and a conventional one

If we compare the process that takes place with a conventional milling machine and a CNC we will realize that there is greater control when the latter is handled. The reason is that the computer allows movements to be made with a precision that would be impossible to do manually. Among them are diagonal lines, circles, and complex three-dimensional figures. The most curious thing is that we are not talking about a worker carrying out this work from the computer, but simply having to program the operations using numerical codes. Thus, they will run on their own.

With the cnc milling machine speed and position of motors are controlled. These are responsible for driving the axes of the machine. It also starts the movement of the table and the spindle. In this way, it will be achieved that all parts of the production are uniform, increasing the quality and precision of the final product.

2 thoughts on “¿Qué es el fresado CNC y como se realiza el proceso correctamente?”

Paredes: se pueden crear salientes y elementos elevados. Sin embargo, recuerda que, en general, suele ser mas asequible mecanizar los elementos sustractivos (grabados), como ranuras, canales u orificios. El fresado CNC es un proceso sumamente versatil que se utiliza en la mayoria de las industrias. Es excelente para producir piezas de precision, en concreto para las industrias automovilistica y aeroespacial, como los componentes del motor, los casquillos o las piezas del sistema de escape. Tambien es un servicio clave para la fabricacion de componentes medicos, sobre todo de prototipos.