Do you know how to structure a cylinder machining line to optimize the job? It is a complex process that must be controlled to the millimeter so that any action that takes place be excellent, whether to create a part or to work on the operation of a machine. On the other hand, when make any instrument for a factory, it must be taken into account that what the latter is mainly looking for is a maximum efficiency in all possible aspects. In this way, you always have to work aiming do the same job in the shortest amount of time, as long as the word quality is shown in the forms, in the resistance and in all the materials used in this aspect.

On Mediavilla workshops We work to meet all the goals you want to achieve. Of course, it is not easy to obtain the above, but for this we have the best professionals and with a great experience that allows us create an excellent line of work. Our goal is that our customers feel satisfied from start to finish. We understand that they are always intended achieve the highest profits and, therefore, we analyze each company in a personalized way, thinking about its products and services, and its mode of operation, to improve your tactics and strategies. There is nothing like getting each step closer to the point you want to get to.

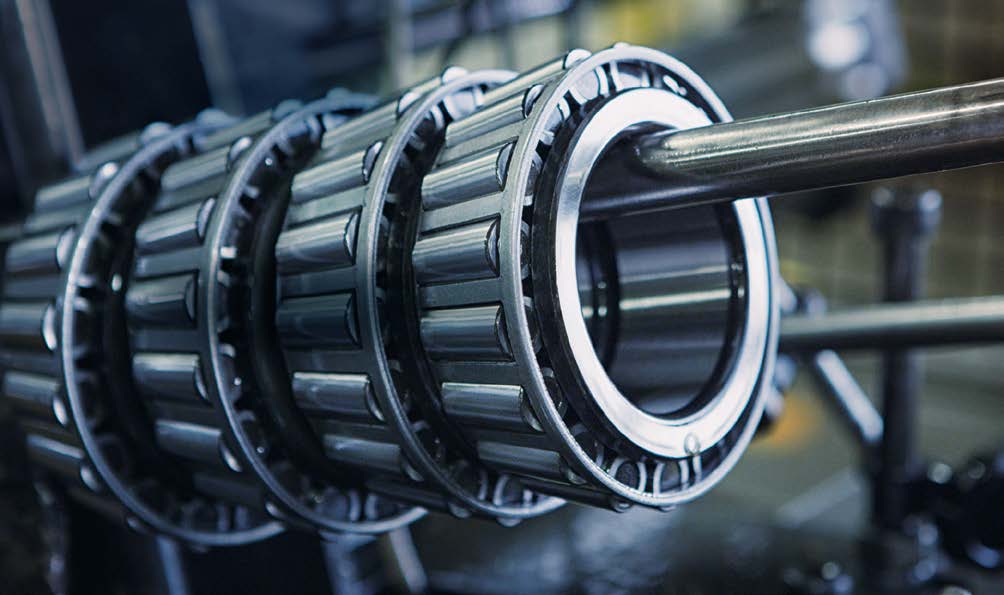

Manufacture of a cylinder machining line to optimize work

To create a cylinder machining line to optimize work It is important to bear in mind that the properties of these pieces must be optimal. Therefore, the process is complex. Therefore, you have to take into account many key features in order for everything to work as planned. In this way, it is usual to divide this work into two parts. One of them is pre-machining and the other is based on creating fine machining. The steps are the following:

- Development of action tools they have to be equipped with at least twenty interchangeable plates.

- He use of adapters allows you to improve the accuracy of creation throughout the entire process.

- With the slide drive it is possible to improve the control of the machines. Likewise, these have to be prepared for an automatic change of the tools that are going to be used. For this, use a coupling improve the efficiency of this step.

- The drawbar movements they are transferred to the slides through tungsten carbide ramps that boast high wear resistance.

- The spindles They are essential to achieve correct machining, thus ensuring the reliability of the process.

With all of the above, it is achieved that the professionals of a specific company don't have to carry too much weight when carrying out their work. On the other hand, the safety in any industry increases by not having to force workers to make an overexertion in their tasks. On Mediavilla workshops We always get involved to achieve all of the above. Ask us without obligation.